How To Do Stock Replenishment

The 9 steps to placing optimal replenishment orders A review of stock-outs and items with excess inventory will generally lead to the conclusion that the orders placed were incorrect. This process involves filling out a complicated form that you can get from your Replenishment Manager RM at Walmart.

Plan To Fulfill P2f Softeon How To Plan Life Cycle Management Supply Chain Solutions

Plan To Fulfill P2f Softeon How To Plan Life Cycle Management Supply Chain Solutions

A key responsibility of every stock replenishment team is to negotiate the best price for the items they reorder so that the sell-on price can be as profitable as possible.

How to do stock replenishment. 5 Easy Stock Replenishment Tips to Limit Out of Stocks. How inventory replenishment works Depending on the unique structuring of your business a team or series of teams will be compiled to oversee inventory. For instance if you stock 1000 pillows you may set your reorder point to when 200 pillows remain in your inventory.

Automate Inventory Replenishment With Good Metrics. Reorder Point average demand during the lead time lead time safety stock As a business owner you can choose to review your stock on a continuous or periodic cycle. Inventory replenishment also called stock replenishment describes the process of getting new stock back to your pick area.

In periodic stock replenishment method the inventory levels of the products are reviewed at a set time period. Various shifts available pay rate from 9 to 11ph. Retailers can automate replenishment using intelligent algorithms which can be particularly beneficial during promotional or seasonal events.

Keep in mind that your pick area encompasses more than a physical area in the warehouse -- it also includes a virtual pick area so to speak. Whilst there are many factors that contribute to stock-outs and excess the best chance you have of getting and keeping your inventory in balance is by placing. If you continually struggle with either excess stock or stock-outs it can be concluded that some assistance with creating the optimal order is required and this article will be able to assist with that.

Activate Replenishment Strategies for storage type. Maintain an accurate forecast. This process can also be thought of as moving items from upstream in the warehouse process to downstream.

Periodic Stock Replenishment Method. Go to Warehouse management Setup Replenishment Replenishment templates. Depending on specific inventory needs a replenishment order can be placed or not but only at the review point.

On the Action Pane click New. Safety Stock Maximum Daily Usage x Maximum Lead Time Days - Average Daily Usage x Average Lead Time Days Now its just a matter of making sure its always implemented. Basically you need to replace stock that you sold - replenish inventory.

This is the basic formula you can apply to get your safety stock numbers. Replenishment is typically initiated either by an inventory policy such as the MinMax inventory method or by a backorder triggered by a client order that could not be fulfilled by the stock on hand. Now that you have your minimum you need to set a maximum inventory level to prevent overstock.

Considering that every order placed is tying up critical working. Stock replenishment is a standard retail practice to ensure that the right products are in the best place at the optimum quantity. Submit a Store Specific Order SSO If you have stores with low instocks you can submit a store supplemental order to get your instocks back up to your goal.

Warehouse or stock replenishment involves moving inventory from its reserve status to primary storage so that it is ready to be picked packed and shipped when a customer places an order. If the stock level or the projected stock level some supply planning systems will trigger a replenishment based upon a projected stock level rather than a current stock level is below the order point then a new replenishment order is created. Consider implementing a collaborative planning forecasting and replenishment CPFR process to align supply and demand.

Collect Stocking Data in the Field. Usually these teams consist of the warehouse managers andor planners who focus on ensuring that the company has enough stock to produce goods andor fulfill orders. Replenishment managers own the forecast and it must accurately reflect the need in the market and avoid surpluses and out of stocks.

In the Replenish template field type a value. What Is Warehouse Replenishment. In supply chain the stock replenishment is an operation that consists in ordering more stocks in order to fulfill the customer demand.

The best chance you have of keeping your inventory in balance is by placing the best possible replenishment order every time. Check the immediate warehouse task creation indicator active. Or you could just use our SSO generator.

Data from your retail locations can be a powerful indicator of how your replenishment process should shake out. The replenishment template is used to define the items and quantities and the location to replenish. With a continuous review inventory is constantly monitored and once the amount of inventory reaches a specified reorder point you place an order.

If you use the reorder point strategy you select a stock level that signals when its time to reorder inventory. If you are available immediately for temporary assignments and commutable to this area please send in your CV asap and we will be back in touch to get you registered. This method is ideal for restocking the items in a warehouse.

SPROEWM Internal warehouse process Replenishment control Activate Replenishment strategies in storage type. But when looking at the bigger picture the best-price is not always the most cost-effective way to procure a product. We need stock replenishment staff to help restock the shelves in this supermarket in Chippenham.

So It S Not Surprising That Many Are Looking For More Accurate Demand Forecasting And Intelligent Stock Replenishment In A Report Enti Forecast Retail Seventh

So It S Not Surprising That Many Are Looking For More Accurate Demand Forecasting And Intelligent Stock Replenishment In A Report Enti Forecast Retail Seventh

Demand Driven Replenishment Ddmrp In S 4 Hana Configuration Setup Driving Hana Pareto Principle

Demand Driven Replenishment Ddmrp In S 4 Hana Configuration Setup Driving Hana Pareto Principle

Determine Warehouse Logistics Requirements Warehouse Logistics Packaging Logistics

Determine Warehouse Logistics Requirements Warehouse Logistics Packaging Logistics

I Used The Back Stock That I Store In The Black Labeled Bins To Replenish All Of The Grab And Go Stacking Bins In My Pantry Stacking Bins Bins The Black Label

I Used The Back Stock That I Store In The Black Labeled Bins To Replenish All Of The Grab And Go Stacking Bins In My Pantry Stacking Bins Bins The Black Label

Inventory At Your Fingertips A Perfect Business Person Knows When His Stock Runs Low And Pla Inventory Management Software Business Person Inventory Management

Inventory At Your Fingertips A Perfect Business Person Knows When His Stock Runs Low And Pla Inventory Management Software Business Person Inventory Management

Smart Supply Replenishment Tool On Behance Smart Cool Things To Make How To Apply

Smart Supply Replenishment Tool On Behance Smart Cool Things To Make How To Apply

Supply Chain Management Scm Pull Replenishment Https Flevy Com Browse Flevypro Doc 3019 The Deve Supply Chain Management Supply Chain Business Management

Supply Chain Management Scm Pull Replenishment Https Flevy Com Browse Flevypro Doc 3019 The Deve Supply Chain Management Supply Chain Business Management

10 Ways To Optimize Your Inventory Management System Inventory Management Software Optimization Management

10 Ways To Optimize Your Inventory Management System Inventory Management Software Optimization Management

Audit Your Inventory Inventory Cost Packaging This Or That Questions

Audit Your Inventory Inventory Cost Packaging This Or That Questions

Here Are 10 Questions That Take The Pulse Of A Company S Inventory Health They Are Designed To Assess The Effective This Or That Questions Safety Stock Health

Here Are 10 Questions That Take The Pulse Of A Company S Inventory Health They Are Designed To Assess The Effective This Or That Questions Safety Stock Health

Reliable Stock Management Assignment Help Inventory Management Writing Services Assignment Writing Service Academic Writing Services

Reliable Stock Management Assignment Help Inventory Management Writing Services Assignment Writing Service Academic Writing Services

Designing A Flexible Distribution Center For Better Space Utilization Supply Chain Management Supply Chain Business Marketing Plan

Designing A Flexible Distribution Center For Better Space Utilization Supply Chain Management Supply Chain Business Marketing Plan

Smart Supply Replenishment Tool On Behance Design System Cool Things To Make Smart

Smart Supply Replenishment Tool On Behance Design System Cool Things To Make Smart

Warehouse Inventory Management System Warehouse Management System Warehouse Management System

Warehouse Inventory Management System Warehouse Management System Warehouse Management System

Cloud Based Erp Software For Warehouse Management Systems In Hyderabad India Warehouse Management System Warehouse Management Cloud Based

Cloud Based Erp Software For Warehouse Management Systems In Hyderabad India Warehouse Management System Warehouse Management Cloud Based

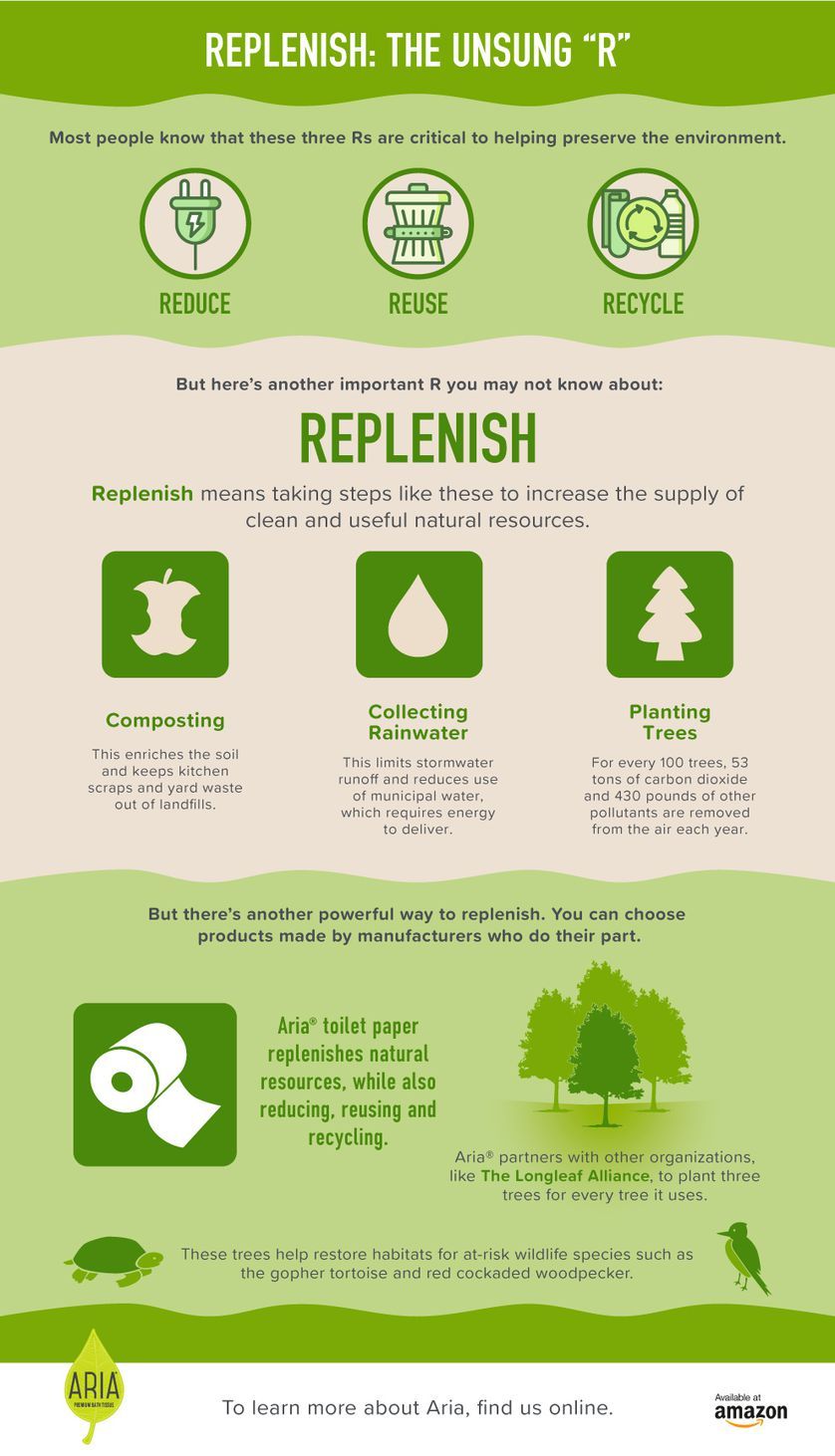

Replenish The Unsung R Replenish Reduce Reuse Recycle Green Design

Replenish The Unsung R Replenish Reduce Reuse Recycle Green Design

Smart Inventory System Flowchart Imagine Retail Management System Software For Footwear And Apparel Stores Flow Chart Retail Inventory

Smart Inventory System Flowchart Imagine Retail Management System Software For Footwear And Apparel Stores Flow Chart Retail Inventory

Post a Comment for "How To Do Stock Replenishment"