How To Calculate Stock Replenishment

To calculate the reorder level multiply the average daily usage rate by the lead time in days for an inventory item. Fill in the batch job request window to limit the scope of the replenishment suggestions that will be calculated.

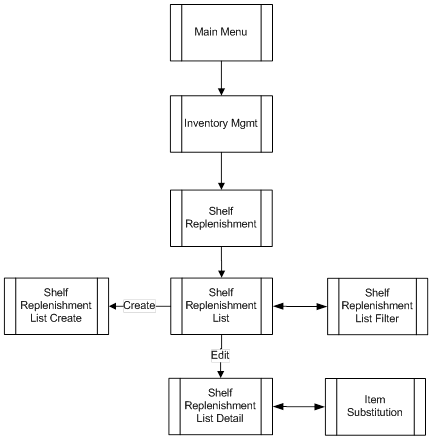

Smart Inventory System Flowchart Imagine Retail Management System Software For Footwear And Apparel Stores Flow Chart Retail Inventory

Smart Inventory System Flowchart Imagine Retail Management System Software For Footwear And Apparel Stores Flow Chart Retail Inventory

Core inventory is inventory that remains in-stock all year round.

How to calculate stock replenishment. Safety stock is the amount of inventory a business needs to have to achieve a certain level of risk mitigation when it comes to stockouts. Inventory levels are continuously reviewed to trigger replenishment either re-ordering or re-stocking when inventory falls below the minimum threshold. 2 5 30 7 3 47 days of sales.

Whilst there are many factors that contribute to stock-outs and excess the best chance you have of getting and keeping your inventory in balance is by placing. To replenish pick bins Choose the icon enter Movement Worksheet and then choose the related link. Choose the Calculate Bin Replenishment action to open the report request page.

Maintain adequate safetybuffer stock levels. - Free Excel Help Home. Here are a few Archon Optical purchase for the last three month of Ghost shipments.

The following video explains how to calculate safety stock in order to avoid the high costs of inventory shortages and stock-outs. There are typically two types of inventory. The definition of standard deviation is a quantity calculated to indicate the extent of deviation for a group as a whole.

But knowing the lead time alone isnt enough. The video explains invento. Add the total delivery time 15 days and divide it by the number of orders 3 orders.

Choose the Calculate Bin Replenishment action to open the report request page. The 9 steps to placing optimal replenishment orders A review of stock-outs and items with excess inventory will generally lead to the conclusion that the orders placed were incorrect. This method is ideal for restocking the items in a warehouse.

So in Month of Jan2011 the Closing stock is 1270 need a formula to calculate how many weeks will this stock cover look at future forecast. In supply chain the stock replenishment is an operation that consists in ordering more stocks in order to fulfill the customer demand. For the most accurate calculations youll want to use as many data points as possible.

Total Required Inventory TRI Average period demand Replenishment time 1X where X 20-40 and the of bins TRI container or bin size 5. Total Required Inventory Average period demand Replenishment time 1 or 2 sigma safety stock 4. Thats an average lead time of five days for the product to arrive.

When determining how much to reorder take your minimum 200 and subtract it from your max 1000 which results in an order quantity of 800 pillows. Inventory replenishment models help businesses determine and manage replenishment frequency establish inventory slotting best practices track the flow of products calculate the quantity of items to order and determine the optimum level of inventory to be. How to Calculate Inventory Turnover.

For example Wilberforce Products experiences average daily usage of its black widget of 100 units and the lead time for procuring new units is eight days. Basic Order Point Logic. In periodic stock replenishment method the inventory levels of the products are reviewed at a set time period.

To replenish pick bins Choose the icon enter Movement Worksheet and then choose the related link. There are a few different ways to calculate inventory turnover which well outline below. Fill in the batch job request page to limit the scope of the replenishment suggestions that will be calculated.

RLT calculation is performed in form END_OF_RLT_CALCULATE which is called from function module AVAILABILITY_CHECK form AVAILABILITY_CHECK_R3. Lets say were analyzing a year-long time period. Depending on specific inventory needs a replenishment order can be placed or not but only at the review point.

Several different pieces contribute to calculating instocks and determining replenishment. Periodic Stock Replenishment Method. There are different ways to calculate this but a three-month average is a good start.

Thus the reorder level is 100 units x 8 days 800 units. Seasonal inventory consists of products you bring in for a specific period of time. Order Point Forecast Safety Stock SS Safety Stock is the buffer to accommodate natural variations in demand and supply.

Youll also need to figure out the demand during this period. For a business to succeed maintaining its stock and replenishing out-of-stock items is essential. Replenishment is typically initiated either by an inventory policy such as the MinMax inventory method or by a backorder triggered by a client order that could not be fulfilled by the stock on hand.

Since it takes J Timewear 47 days to get a new shipment of watches theyll need to have enough stock on hand to cover these 47 days of sales. The order point is managed in the Order Point Calc Analytic and is calculated by adding the forecast during the lead time plus the safety stock. Calculating Safety Stock When dealing with uncertainties and multiple variables the best way to calculate safety stock is to use standard deviation to determine variations in supply and demand.

If a business fails to address each of these parts it is in jeopardy of losing customers. In order to enable the calculation of the replenishment lead time for availability check the field Check without RLT V_441V-OWBZP in the scope of check transaction OVZ9 must be empty. Inventory Replenishment Formula - Is there a formula for figuring out inventory.

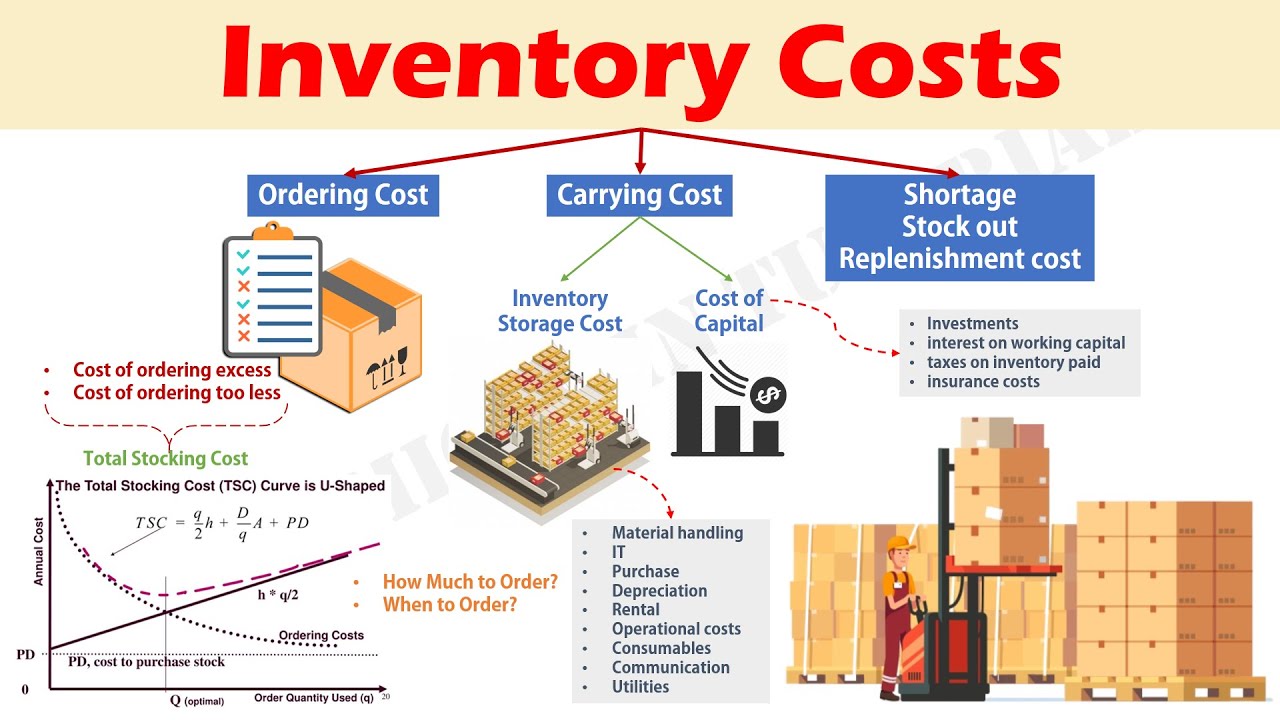

Components Of Inventory Costs Ordering Cost Carrying Cost Stock Out Cost Cost Of Replenishment Youtube

Components Of Inventory Costs Ordering Cost Carrying Cost Stock Out Cost Cost Of Replenishment Youtube

Understanding Par Location Management

Understanding Par Location Management

What Is Stock Replenishment Methods And Calculation Orderhive

What Is Stock Replenishment Methods And Calculation Orderhive

5 Inventory Replenishment Methods Part 1 Of 5 Mrp Fastening Supply And Inventory Management Falcon Fastening Solutions

5 Inventory Replenishment Methods Part 1 Of 5 Mrp Fastening Supply And Inventory Management Falcon Fastening Solutions

Multi Card Kanban Inventory Replenishment Part 2 3 Fastening Supply And Inventory Management Falcon Fastening Solutions

Multi Card Kanban Inventory Replenishment Part 2 3 Fastening Supply And Inventory Management Falcon Fastening Solutions

Crp Continuous Replenishment Program Lean Manufacturing

Reorder Point Planning Theoretical Construct Jpg 720 540

Reorder Point Planning Theoretical Construct Jpg 720 540

Audit Your Inventory Inventory Cost Packaging This Or That Questions

Audit Your Inventory Inventory Cost Packaging This Or That Questions

Does Your Inventory Replenishment Model Fit Your Goals

Does Your Inventory Replenishment Model Fit Your Goals

5 Inventory Replenishment Methods That Increase Profits Eazystock

5 Inventory Replenishment Methods That Increase Profits Eazystock

Purchase Order Form D3 What Makes Purchase Order Form D3 So Addictive That You N Purchase Order Form Personal Financial Statement Financial Statement Analysis

Purchase Order Form D3 What Makes Purchase Order Form D3 So Addictive That You N Purchase Order Form Personal Financial Statement Financial Statement Analysis

Mastering Replenishment To Save Time Money And Grow Your Business Growing Your Business Business Process Management How To Motivate Employees

Mastering Replenishment To Save Time Money And Grow Your Business Growing Your Business Business Process Management How To Motivate Employees

Purchase Order Management System Pos Highway Order Management System Management Purchase Order

Purchase Order Management System Pos Highway Order Management System Management Purchase Order

Here Are 10 Questions That Take The Pulse Of A Company S Inventory Health They Are Designed To Assess The Effective This Or That Questions Safety Stock Health

Here Are 10 Questions That Take The Pulse Of A Company S Inventory Health They Are Designed To Assess The Effective This Or That Questions Safety Stock Health

Stock Inventory Control Spreadsheet With Count Sheet Excel Spreadsheets Templates Spreadsheet Template Invoicing Software

Stock Inventory Control Spreadsheet With Count Sheet Excel Spreadsheets Templates Spreadsheet Template Invoicing Software

How To Determine Efficient Replenishment Frequency When Managing Your Inventories Soft4inventory

Post a Comment for "How To Calculate Stock Replenishment"